A Complete Guide to Medicine Box and Label Printing

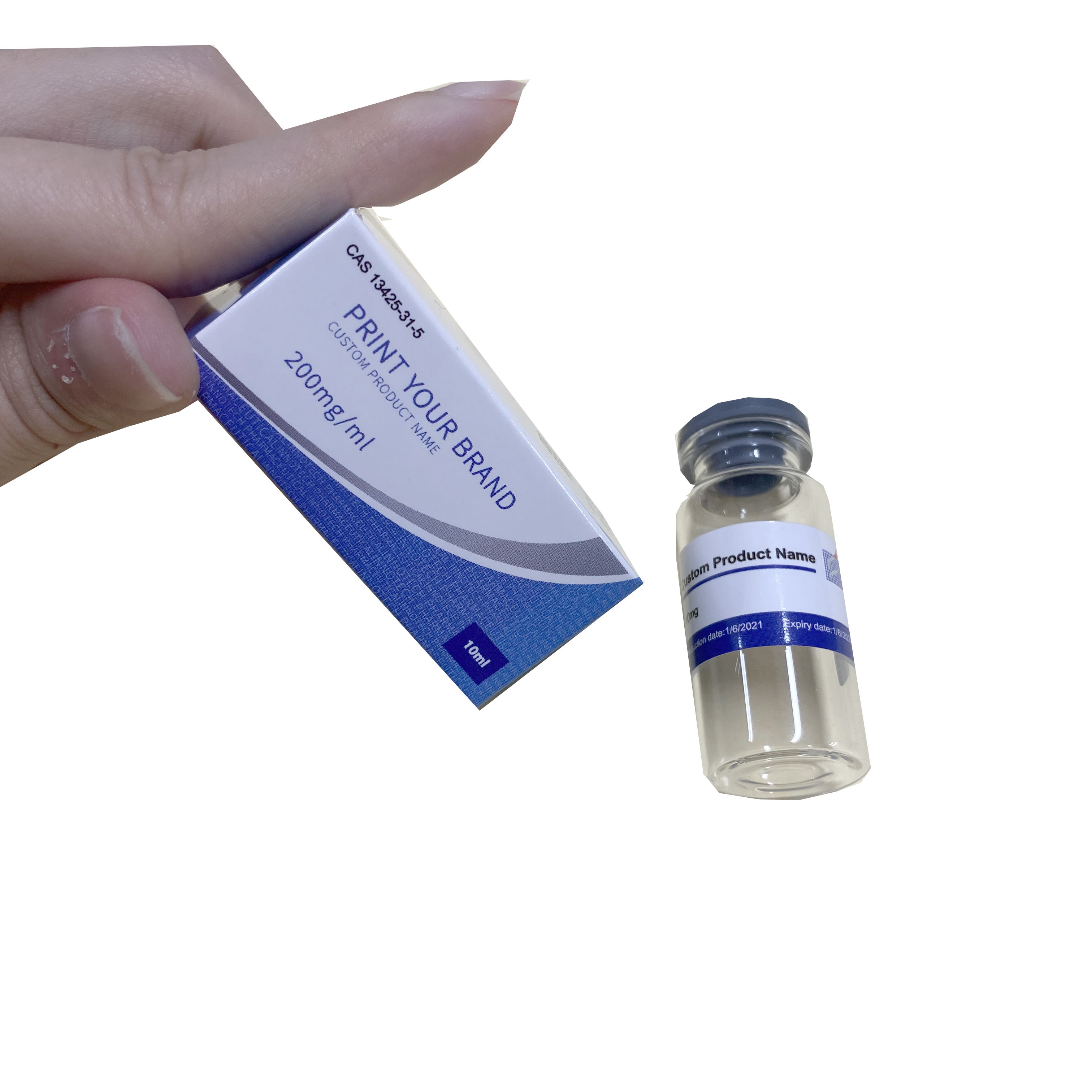

Pharmaceutical packaging is more than just a container for medication—it plays a critical role in ensuring patient safety, adhering to regulatory standards, and protecting the drug’s integrity. Medicine box and label printing is a complex process that requires a precise understanding of design, materials, and compliance with various standards.

Definition and Function of Medicine Boxes and Labels

Medicine boxes and labels are essential components of pharmaceutical packaging. The primary function of a medicine box is to protect the medication from external factors such as moisture, light, and physical damage. The box serves as the first line of defense for the drug, ensuring it reaches the consumer in its intended condition. Additionally, the medicine box must convey important information about the product, including dosage instructions, expiration dates, and safety warnings.

The label on the medicine box, on the other hand, provides more specific details about the medication. This includes the drug's active ingredients, possible side effects, storage instructions, and any necessary warnings. The label is also a vital tool for healthcare professionals, helping them to make informed decisions about prescribing the drug. With modern printing technologies, labels also include anti-counterfeiting features, which are increasingly important in the global pharmaceutical market.

Pharmaceutical Packaging Regulations

The printing of medicine boxes and labels is strictly regulated by various authorities, including the National Medical Products Administration (NMPA) in China, the U.S. Food and Drug Administration (FDA), and the European Medicines Agency (EMA). These regulations ensure that pharmaceutical packaging is not only safe but also consistent and reliable across different markets.

Each regulatory body has specific guidelines that packaging manufacturers must follow. For example, the FDA requires that pharmaceutical packaging include critical information such as the National Drug Code (NDC), the drug’s ingredients, dosage instructions, and specific warnings. Similarly, the EMA has detailed rules on packaging design and labeling, particularly for products sold in Europe.

In addition to safety and content regulations, there are guidelines concerning the durability of packaging materials and the readability of printed information. The goal is to ensure that the packaging protects the drug while providing consumers with clear and accessible instructions.

Common Medicine Box Materials

The choice of materials used for medicine boxes directly impacts the effectiveness of the packaging, both in terms of protection and presentation. Common materials for medicine boxes include:

White Cardboard

White cardboard is a widely used material for medicine boxes due to its smooth surface, which is ideal for high-quality printing. This material offers excellent durability and protection while maintaining an aesthetically appealing finish. White cardboard is commonly used for over-the-counter medications and prescription drugs, as it provides a clean, professional appearance.

Grey Cardboard

Grey cardboard is often used for more economical packaging options. It is durable and cost-effective, making it a popular choice for generic drugs or products where premium presentation is less of a priority. Despite its lower cost, grey cardboard still provides sufficient protection for pharmaceutical products.

Gold and Silver Cardboard

Gold and silver cardboard are premium materials often used for high-end pharmaceutical products, such as specialty medications, luxury cosmetics, or health supplements. These materials are often coated with metallic finishes, which enhance the packaging's visual appeal and create a sense of exclusivity. Gold and silver cardboard also help to distinguish a brand and make it stand out on the shelf.

Label Materials

The materials used for medicine labels are just as crucial as those for the box. The label must adhere to the box securely while being legible and resistant to wear and tear. Common materials for labels include:

Coated Paper

Coated paper is frequently used for medicine labels due to its smooth finish and excellent printability. The coating enhances the vibrancy of the print and ensures that the label can withstand handling without fading or smudging. This material is suitable for most pharmaceutical packaging, including both large-scale and custom label applications.

Self-adhesive Labels

Self-adhesive labels are used in a variety of pharmaceutical packaging, especially for products that require easy application and removal. These labels are ideal for products that need to be tagged or labeled after packaging, such as specialty medications or personalized medicine.

PET and PVC

Polyethylene Terephthalate (PET) and Polyvinyl Chloride (PVC) are materials often used for labels on pharmaceutical products requiring durability and resistance to moisture or chemicals. These materials are particularly beneficial for products that need long-term shelf life and consistent labeling throughout distribution.

Easy-tear Film

Easy-tear film is used for packaging that requires tamper-evident seals or easy-to-open features. This material is commonly used for over-the-counter medications and consumer products where ease of access is essential without compromising the integrity of the package.

Medicine Box Structure Types

The structure of the medicine box can vary depending on the type of product being packaged. Common medicine box structures include:

Slot Boxes

Slot boxes are simple, foldable boxes with slots for assembling. They are commonly used for smaller pharmaceutical products, such as blister packs of pills. These boxes are lightweight and easy to assemble, making them a cost-effective option for packaging.

Drawer Boxes

Drawer boxes are designed to slide open like a drawer, making them an excellent choice for products that require additional security or aesthetic appeal. These boxes are often used for high-end pharmaceutical products or gift sets, providing both protection and a premium experience.

Top and Bottom Boxes

Top and bottom boxes are two-piece packaging designs where the top lid fits over the base. This structure is commonly used for larger products or items that need more robust protection. The top and bottom box structure provides excellent durability while offering a clean and simple design for pharmaceutical packaging.

Medicine Box Printing Process

The printing process for medicine boxes involves multiple stages, each crucial to ensuring high-quality and compliant packaging. The process includes:

Design

The design stage is where the blueprint for the medicine box is created. This step includes layout planning, typography selection, and the placement of essential elements like logos, text, warnings, and other regulatory information. The design must adhere to industry standards while being visually appealing and legible.

Proofing

Proofing is the stage where the design is reviewed and approved before actual printing begins. This step involves creating a sample of the design to ensure that colors, fonts, and layout are correct. Proofing is a critical quality control measure that ensures the final product meets the required standards.

Printing

Once proofing is complete, the printing stage begins. This step involves transferring the design onto the selected material using one of several printing techniques, such as offset or flexographic printing. The choice of printing method depends on the material and the quantity of boxes being produced.

Lamination

Lamination is a finishing process that adds a protective layer to the printed box. It helps preserve the print and increases the durability of the packaging. Lamination can also enhance the visual appeal of the box by adding a glossy or matte finish.

Die-cutting

Die-cutting is the process of cutting the printed material into the desired shape and size. This step is essential for creating boxes that are easy to assemble and visually appealing. Die-cutting can also be used to create unique shapes or window openings for product display.

Gluing

Finally, gluing is used to assemble the box. The components are glued together, forming the final structure of the medicine box. Gluing ensures that the box is sturdy and secure, preventing it from falling apart during transport or handling.

Pharmaceutical Label Printing Process and Layout Standards

The printing of pharmaceutical labels follows a process similar to that of medicine boxes. It includes design, proofing, printing, and finishing. Additionally, label layout standards ensure that all regulatory information is clearly presented. These standards specify where the text should be placed, the font size for readability, and the inclusion of key information like the drug's ingredients, expiration date, and warnings.

Anti-counterfeiting and Traceability

With the increasing risk of counterfeit drugs, pharmaceutical companies are incorporating various anti-counterfeiting features into their packaging. These include:

QR Codes

Allow consumers and healthcare providers to verify the authenticity of the product by scanning the code.

Laser Film

Used to create tamper-evident packaging that changes color or texture when disturbed.

UV Ink

Invisible ink that can only be seen under ultraviolet light, providing an additional layer of security.

Scratch Coating

A coating that reveals hidden information when scratched, adding another layer of security against counterfeiting.

Multilingual and International Standards for Exported Pharmaceutical Packaging

For pharmaceutical products sold internationally, the packaging must adhere to multilingual and international standards. This ensures that labels are understandable to consumers and healthcare providers in different countries. Regulations may require that labels include specific languages, symbols, and formats based on the country of sale. It is crucial for companies to be aware of these requirements when exporting drugs to ensure compliance with local laws.

How to Choose a Suitable Printing Plant

When selecting a printing plant for your pharmaceutical packaging, there are several factors to consider:

Price

Cost is always a consideration, but it’s important to balance cost with quality. Choose a plant that offers competitive pricing without sacrificing quality or compliance with industry standards.

Proofing Time

The proofing stage is critical for ensuring that the final design meets all requirements. A reliable printing plant should offer a fast and efficient proofing process.

Document Requirements

Ensure that the printing plant understands the necessary regulatory documents and requirements for pharmaceutical packaging. The plant should be able to handle compliance with various international regulations.

FAQ

What are the most commonly used materials for medicine boxes?

Common materials for medicine boxes include white cardboard, grey cardboard, and gold or silver cardboard. White cardboard is popular for its smooth finish and durability, while grey cardboard offers a more cost-effective solution. Gold and silver cardboard are often used for premium pharmaceutical products.

How do anti-counterfeiting features work on pharmaceutical packaging?

Anti-counterfeiting features help prevent the distribution of counterfeit drugs by adding security elements such as QR codes, laser films, UV ink, and scratch coatings to the packaging. These features allow consumers and healthcare providers to verify the authenticity of the product and protect against tampering.

What is the difference between slot boxes and drawer boxes?

Slot boxes are simple, foldable boxes with slots for assembling and are commonly used for smaller pharmaceutical products. Drawer boxes, on the other hand, slide open like a drawer and are used for products that require a more secure and aesthetic packaging design, often for premium products.

Why is multilingual labeling important for international pharmaceutical products?

Multilingual labeling ensures that pharmaceutical packaging complies with regulatory requirements in different countries. It makes the product accessible to consumers and healthcare providers in various regions and ensures that the necessary information is communicated clearly and accurately.

Table of Contents

- A Complete Guide to Medicine Box and Label Printing

- Definition and Function of Medicine Boxes and Labels

- Pharmaceutical Packaging Regulations

- Common Medicine Box Materials

- Label Materials

- Medicine Box Structure Types

- Medicine Box Printing Process

- Pharmaceutical Label Printing Process and Layout Standards

- Anti-counterfeiting and Traceability

- Multilingual and International Standards for Exported Pharmaceutical Packaging

- How to Choose a Suitable Printing Plant

- FAQ