envelope factory

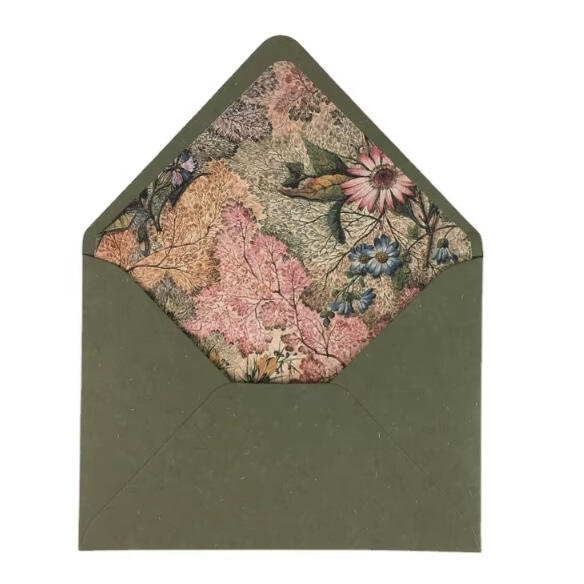

An envelope factory represents a sophisticated manufacturing facility dedicated to producing various types of envelopes through automated processes and advanced machinery. Modern envelope factories utilize state-of-the-art equipment that combines cutting, folding, gluing, and printing operations in streamlined production lines. These facilities are capable of producing thousands of envelopes per hour, ranging from standard business envelopes to specialized security and decorative varieties. The factory incorporates quality control systems that monitor envelope dimensions, adhesive application, and overall product integrity. Advanced die-cutting machines ensure precise measurements while automated folding units create clean, professional creases. The production process begins with raw paper selection, progresses through cutting and scoring stages, and concludes with finishing operations including gumming and packaging. Modern envelope factories also feature digital printing capabilities for customization options, allowing for immediate design modifications and brand-specific requirements. Environmental controls maintain optimal temperature and humidity levels to ensure consistent product quality, while waste reduction systems promote sustainability through material recycling and efficient resource utilization. The facility's workflow management system coordinates all operations, from inventory control to shipping logistics, ensuring timely order fulfillment and customer satisfaction.