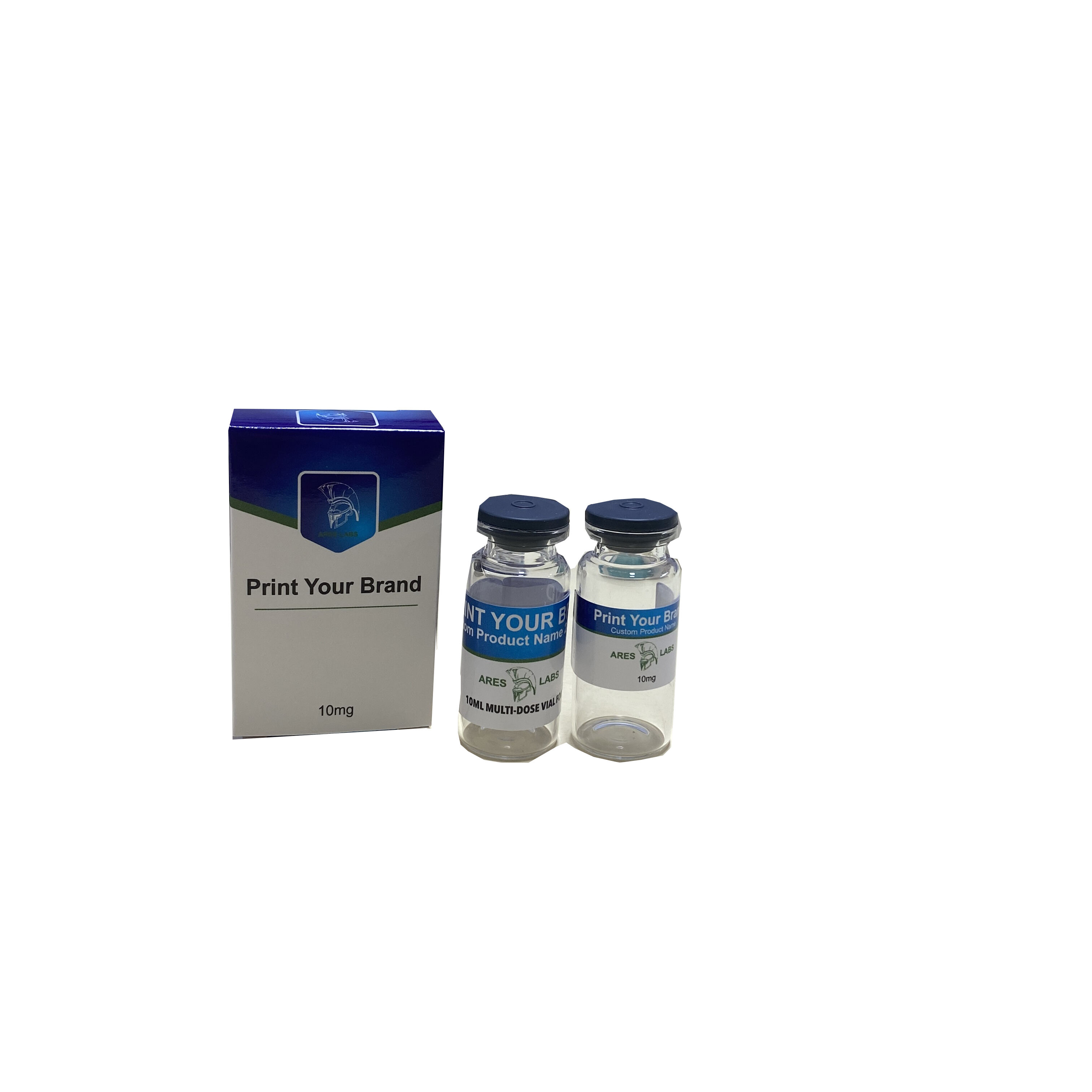

10ml vial label

The 10ml vial label represents a crucial component in pharmaceutical and laboratory settings, designed specifically for accurate identification and tracking of liquid contents. These labels feature advanced adhesive technology that ensures reliable adherence to glass, plastic, and other vial materials, even in challenging storage conditions including freezer environments and high humidity. The labels are manufactured with high-quality materials that resist fading, smearing, and degradation from common laboratory chemicals and solvents. Each label incorporates a specialized writing surface that accommodates both handwritten notes and various printing methods, including thermal transfer and direct thermal printing. The dimensions are precisely calibrated to fit standard 10ml vials while providing adequate space for essential information such as content description, concentration, preparation date, expiration date, and batch numbers. The labels feature enhanced clarity and readability through optimized font sizes and contrast ratios, ensuring critical information remains visible throughout the product's lifecycle. Additionally, these labels comply with GMP standards and regulatory requirements for pharmaceutical labeling, making them suitable for both research and commercial applications.